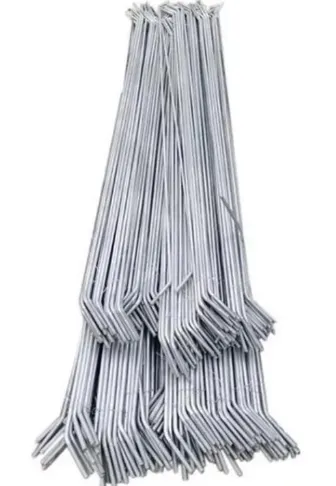

weldingH-beam Product introduction: welding H-shaped steel is a commonly used core component in the field of steel structures. Welded H-shaped steel is an H-shaped cross-section steel formed by combining three steel plates (upper flange plate, lower flange plate, and web plate) through a welding process. It has the characteristics of flexible cross-section size and excellent mechanical properties.

Core features

The cross-section is highly customizable, and the thickness and width of the flange plate and web plate can be adjusted according to engineering needs to adapt to different load conditions.

The mechanical properties are stable, the flange and the web are closely combined, and the bending and shear resistance are better than traditional rolling. H-shaped steel.

The material utilization rate is high, and materials can be cut accurately according to the design, reducing waste and engineering costs.

Main application scenarios

Industrial factory: Beam and column structures used in factories to support large-span spaces.

High-rise buildings: used as frame columns and beams to improve the structural stability and load-bearing capacity of the building.

Bridge engineering: used for the main beams, supports and other parts of bridges to adapt to complex stress environments.

Non-standard equipment: customized production of support structures for special equipment, such as wind power towers and supporting components for nuclear power equipment.

Main points of production process

Blanking cutting: CNC flame cutting or plasma cutting is used to ensure the dimensional accuracy of the steel plate.

Assembly and assembly: Position and assemble the flange plate and web plate through an assembly machine to ensure accurate cross-section verticality and spacing.

Welding operation: Use submerged arc welding or gas shielded welding to control welding parameters to avoid defects such as pores and cracks.

Correction treatment: flame correction or mechanical correction is performed after welding to ensure the straightness and cross-sectional dimensional tolerance of the steel.

We are fully equipped and can process a wide range of products up toIt is a large H-shaped steel with a wing plate width of 3m and a thickness of 120mm, and the quality of the welding seam is guaranteed to reach the first-class flaw detection level.